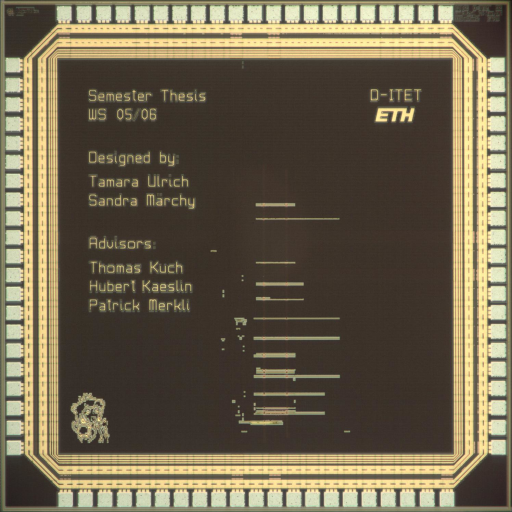

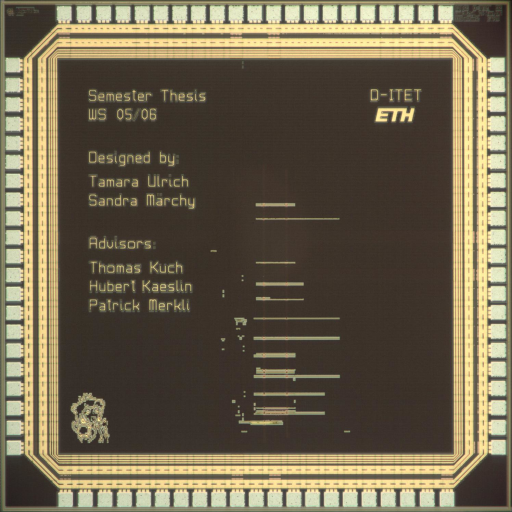

The IIS Chip Gallery

Princesses (2006)

by

| Application | Industrial |

| Technology | 250 |

| Manufacturer | UMC |

| Type | Semester Thesis |

| Package | LCC84 |

| Dimensions | 2500μm x 2500μm |

| Voltage | 2.5 V |

| Clock | 10 MHz |

A classical approach to measuring the flow rate of a liquid is to insert two thermocouples into the flowing medium a few millimetres apart with a heating element sitting in between. The difference between the two voltage readings then is a function of the speed of flow. As the relationship is nonlinear, the signal from a sigma-delta ADC must be translated into a 2?s complement number applying the inverse function.

The goal of the student project was to minimize the hardware costs for doing so under given accuracy constraints. After an evaluation of different interpolation schemes, it has been decided to go for cubic Bézier splines for calculating values that fall between knots previously stored in a look-up table during sensor calibration. For comparison, the alternative of trading a larger number of knots against a simpler linear inpolation scheme has also been pursued.

27 knots were found to be necessary to meet the specifications with the Bézier splines as opposed to 256 with linear interpolation. A spline linearization engine has been designed as a cell-based ASIC. Its hardwired architecture includes three specialized computational units, a finite state machine, and one memory.

In conclusion, the optimum tradeoff was found to depend on the type of memory being instantiated for the look-up table. While spline interpolation reduced circuit area by roughly 20 % when used in conjunction with an SRAM, the better density of a ROM did not justify the more complex spline computation.

The chip is unofficially called princesses due to the fact that two women were the main designers. There is a small princess peaches logo at the bottom left of the chip for this purpose